The Plantin Moretus Museum and a 450-year reflection on publishing

Yesterday I visited the Museum Plantin Moretus in Antwerp. Christophe Plantin was printer who published his first book in 1555. What surprised me most about what I saw was not how much publishing has changed in 450 years, but how much it hasn’t.

Plantin came from Normandy, settled in Antwerp, and started a publishing business called Officina Plantiniana. (Antwerp is in Flanders, in the Northern part of of Belgium.) The museum documents his life and those of his descendants and successors in creating what was for a time one of the biggest publishers in Europe. I took the photos here while visiting the museum, which is full of old books, actual Plantin printing presses, and Rubens paintings — (Peter Paul Rubens was a friend of the Plantins).

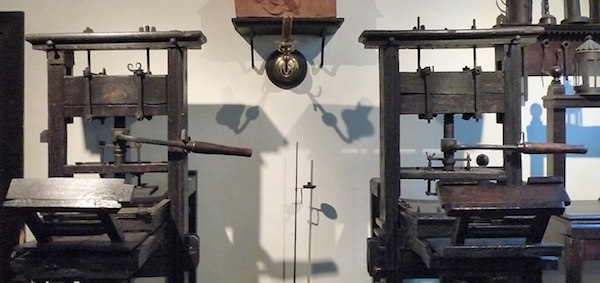

Plantin got his start about 100 years after the production of the first Gutenberg bible, the first book printed with movable type. Plantin was able to take advantage of the established technologies of paper production, ink, presses, and small bits of lead type that could be arranged into a page.

The publishing industry of the 1500s has a very different structure from the way things are now. Plantin was both a publisher and printer; those two industries are very much separate now. In those days, and for centuries afterwards, presses (that is, publishers) owned presses (that is, printing devices). Plantin selected works to publish, had his workmen create and lay out pages from the manuscripts, printed the pages, and arranged for the distribution of books, including selling them himself in some cases.

Interestingly, though, at the time, bookbinding was separate from printing. You’d buy a bound set of pages and bring it to a bookbinder, who would then put a fine binding on it using materials of your choice, typically leather. As a result, 100 copies of the same book might look completely different on the shelf.

Printing in the 1500s was slow. Laying out type required selecting letters from type cases (the “upper case” contained capital letters, the “lower case” included the rest) and placing them one at a time in a frame where, once they were appropriately secured, the printer could apply ink to them and squeeze a paper against them in a press. The press uses mechanical advantage to apply pressure, much like a cider or wine press. When we talk of “the power of the press,” we never think about how, originally, the term “press” comes from the power necessary to manually transfer ink from a frame full of letters to a sheet of paper.

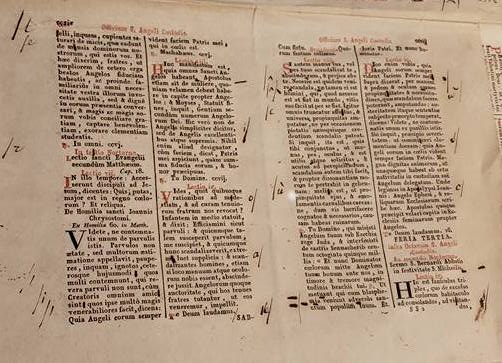

Naturally, press workers would occasionally make errors. The first sheet off the press would go to a room of “correcteurs” who would scrutinize the printed page carefully, looking for mistakes. Correcting a mistake meant going back to the frame full of type and replacing the erroneous letters. This process is exactly analogous to what happens in today’s copy editing and page layout process, only much slower. Contemporary copy editors will notice that Plantin’s correcteurs use proofreading marks that look very similar to the ones that we use today.

Plantin could print in two colors by aligning a second frame of type and overprinting a page — exactly the same process that current printers use. His workers could create graphics by etching a metal plate or creating a woodcut and locking it into place along with the rest of the type. The resulting text-and-graphics page layouts look a lot like the pages we create today.

Naturally, Plantin’s presses did not create one page at a time. He’d print eight, 16, or 32 pages on a sheet, which his workers would carefully fold up and trim to create a block of pages — a “signature.” Today’s printers perform exactly the same operation, only much faster and with machines instead of human labor.

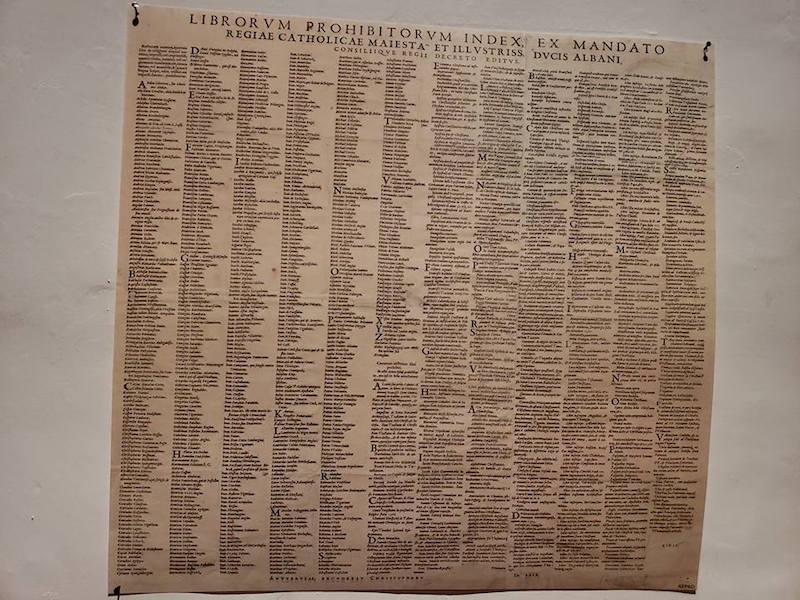

Most of what Plantin printed were religious works in Latin, but his press also produced anatomy and medical texts and scientific treatises. Cracking down on the threat from Protestants, the church created an index of prohibited works (as you may recall, Galileo’s treatise on the heliocentric model of the solar system ended up on this list). Think this doesn’t go on now? In China, all printers must currently register with the government, and while there is no official list of prohibited works, a publisher that printed something that threatens the government would lose its license quickly.

Plantin employed foundries to create type and acquired a variety of typefaces and fonts, including not just the Roman alphabet but arabic and hebrew. The next time you click on a font menu and pull down a list, consider what it mean to have to pull out a whole shelf of metal type every time you wanted to use a different typeface.

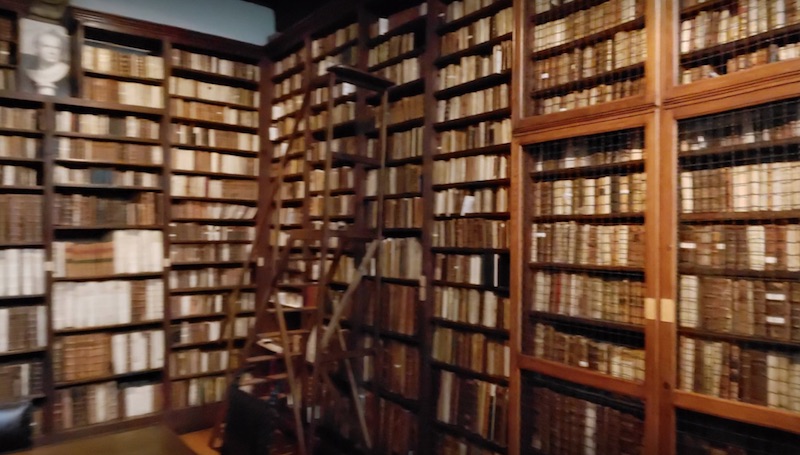

Plantin and his descendants were highly educated, which is what enabled these publishers to select and print works ranging from an elaborate, six-language bible to books of plant remedies to dictionaries in many languages. As you might imagine, his book collection was extensive. His library awed me; if you want to know what education and history smell like, this room will take you there.

The historians who maintain this museum had little to say about the process by which manuscripts became ready to typeset in Plantin’s era. There was no mention of “editors” in the modern sense. I’m guessing here, but I imagine that, given the extreme expense and painstaking labor needed to produce a book, that authors (who had to be either very well educated or rich) had to plan and think carefully before sitting down to handwrite a manuscript (a word that literally means “written by hand”). I wonder if they created multiple drafts before a work became ready for a printer to set it into type. Given the limited number of books the world could create at that time — the fact that the Church could list the entire set of banned books on one sheet of paper is an indication — you’d have to be pretty special to imagine that your thoughts could get into book form. Plantin Press’ prodigious production included a large number of previously published works, like Roman histories and liturgical books, because the risk was lower.

Now any bozo with a word processor can write and distribute printed material. And anyone can print and publish a book on Amazon CreateSpace. I suspect that Plantin and his contemporaries functioned as editors, choosing carefully which potential authors and works were worthy of the effort of publishing. Today’s publishing houses attempt to fill this function as well, but their influence is fading. How will we determine what’s worth publishing and reading in an era where the means of print production are available to everyone?

“The Chamber des Correcteurs” is my least favorite Harry Potter novel.

It’s amazing to look back on both the progress and the cycles in an established industry. While it wasn’t a whole drawer full of lead, I remember desktop (and larger) printers of the 80s that had daisy wheels, Selectric elements, print bands, and other physical manifestations of their typefaces. You want italics? Change the physical element. You want bold? Change the physical element. You want a color other than black or red, change the ribbon. You want to change something you typed? Grab a bottle of White-Out and a brush.

I think you’re right. The act of writing something out long-hand is different in both character and quality from typing something into a word processor. Just knowing you might have to throw away a whole sheet if you make a mistake that you don’t want the recipient to see focuses the mind…

Way back in the last millennium – November 1998, to be exact – I posted something to my company’s intranet under the heading “The written word is dead. The future is video.”

In a generation’s time, it will be every example of the written word in one big museum.

The generation now being born will be the last to be taught to read and write.

Fun to make predictions like this. I think yours is a little too radical.

I was being deliberately outrageous, but I think the principle is right.

Back in the last millennium I also predicted that thanks to the Internet, within 20 years – i.e. right about now – almost all of the developed world’s newspapers would no longer be producing a printed edition on weekdays (and that a decade later there would be no weekend editions printed either). My timeframe has proved to be inaccurate (so far) but the trend is clear.

Thanks for an insightful article. I particularly enjoyed you comment about what “the power of the press” meant originally.

You noted, “Plantin was able to take advantage of the established technologies of paper production, ink, presses, and small bits of lead type that could be arranged into a page.” My concern is that you may be subtly perpetuating one of the erroneous assumptions about Johannes Gutenberg. I heard a keynote speaker at an international conference of the Society of Technical Communicators make that assumption, that printing somehow started with J.G. who invented the presses, paper, ink, etc. Which, of course, he did not. J.G. was brilliant, but even L.DaVinci didn’t create whole industries from scratch.

Printing presses, paper, ink, even movable type existed before Gutenberg’s miraculous invention. But that movable type was carved by hand, one letter at a time out of hardwood. Those individual letters were THE MOST EXPENSIVE part of the whole printing process; they had to have very precise dimensions to be able to rack up into lines of text properly. And if a page of text had 134 “e”s on it, you needed to hand carve all 134 of those “e”s, one at a time, laboriously and hyper-accurately.

Because type was so expensive to create, printers had to wait for the entire print run of one page to be completed before they broke that page down into individual letters and rebuilt them into the next page. That assembly process was the major bottleneck because of the cost of the type. And being wood, press runs were limited because all that expensive type simply wore out. Books were small, short, and only for the rich. (Erotic poetry was a big seller.)

Gutenberg was a gold- and silversmith. He understood metal casting. He looked at all that hand carving of type and knew he could do better. But his idea languished because he was earning a living.

He had a get-rich-quick scheme of making a wagonload of silver and gold religious castings to sell at a religious fair, but he got the date wrong and his investors money was tied up in castings and the fair was another year off and his investors wanted their money back. With that pressure, he decided that the time was right to gamble on his languishing idea.

When he finally was motivated to do it, his brilliant idea was to create a mold system that had one face of the mold removable and interchangeable. That replaceable face received the convex carving that would become the concave casting of the letter form. The rest of the mold stayed the same, ensuring that all letters would have the same height and depth and thus would rack up smoothly and evenly. He could pour hot lead into the mold, let it cool, pop it out of the mold and pour another in a matter of minutes. 134 “e”s on a page? No problem. Done this afternoon.

Because he changed the type from wood to metal, it lasted much longer too. He also had to reformulate the ink, from water-based to oil-based, but that was, of course, not what he was famous for. And other people could help with that.

His invention of the modular mold changed the creation of the type from the most expensive part of the process to cheap and easy. Now while the first page was being printed, you could rack up the type for the second because you had more type available than you needed. You were overflowing with a veritable fountain of type (“font” in French). THAT is what he is justly famous for.

Now the actual press time, the impressions of type to paper, was the bottleneck, and that didn’t change until the end of the 20th Century, when the Internet removed the paper from the process.

(I got these details from a PBS documentary a couple of decades ago, which I have been unable to find again. Having a background in ink-on-paper printing before I got into computer publishing, I was fascinated and remembered the details, if not the sources.)